Why Winter Diesel Care Matters in Tennessee

Tennessee winters can swing from mild mornings to freezing nights, and diesel reacts quickly. Cold thickens fuel, slows cranking, and raises the risk of gelling in small tanks. Moisture also matters because temperature fluctuations can cause condensation inside partially filled tanks. That water can freeze, clog filters, and invite microbial growth during longer storage. Winter diesel care is about three goals: clean fuel, reliable starting, and protected components. Start by using fresh, season-appropriate diesel from a high-turn station. Cold-weather blend varies by supplier and region. Then keep your machine on a simple routine you can repeat weekly. Even if you only plow occasionally, a few minutes of prevention beats a no-start day. This guide covers anti-gel options, smart storage, block-heater tips, and water control. If you want help choosing products or diagnosing issues, Bob’s Tractor Parts can walk you through it.

Anti-Gel Basics: Treat Early, Not After Trouble Starts

Anti-gel is insurance for cold snaps, but it works best before temperatures drop. Most additives lower the fuel’s pour point and help wax crystals stay smaller. However, anti-gel can’t revive fuel that already gelled into a thick slush. So, treat the tank while the fuel is still warm, ideally after filling up. Then drive or run the machine, so treated fuel reaches the lines and filters. Read the label carefully, because treat rates vary by brand and season strength. In Tennessee, watch overnight lows and plan for arctic fronts. In extreme cold, use winter-blend fuel. If you store an additive in a shop, warm the bottle before dosing. Also, choose a lubricity-friendly formula, especially with ultra-low sulfur diesel. Finally, keep spare fuel filters on hand, because a plugged filter feels like gel. Bob’s Tractor Parts can recommend the right additive and filter for your LS tractor.

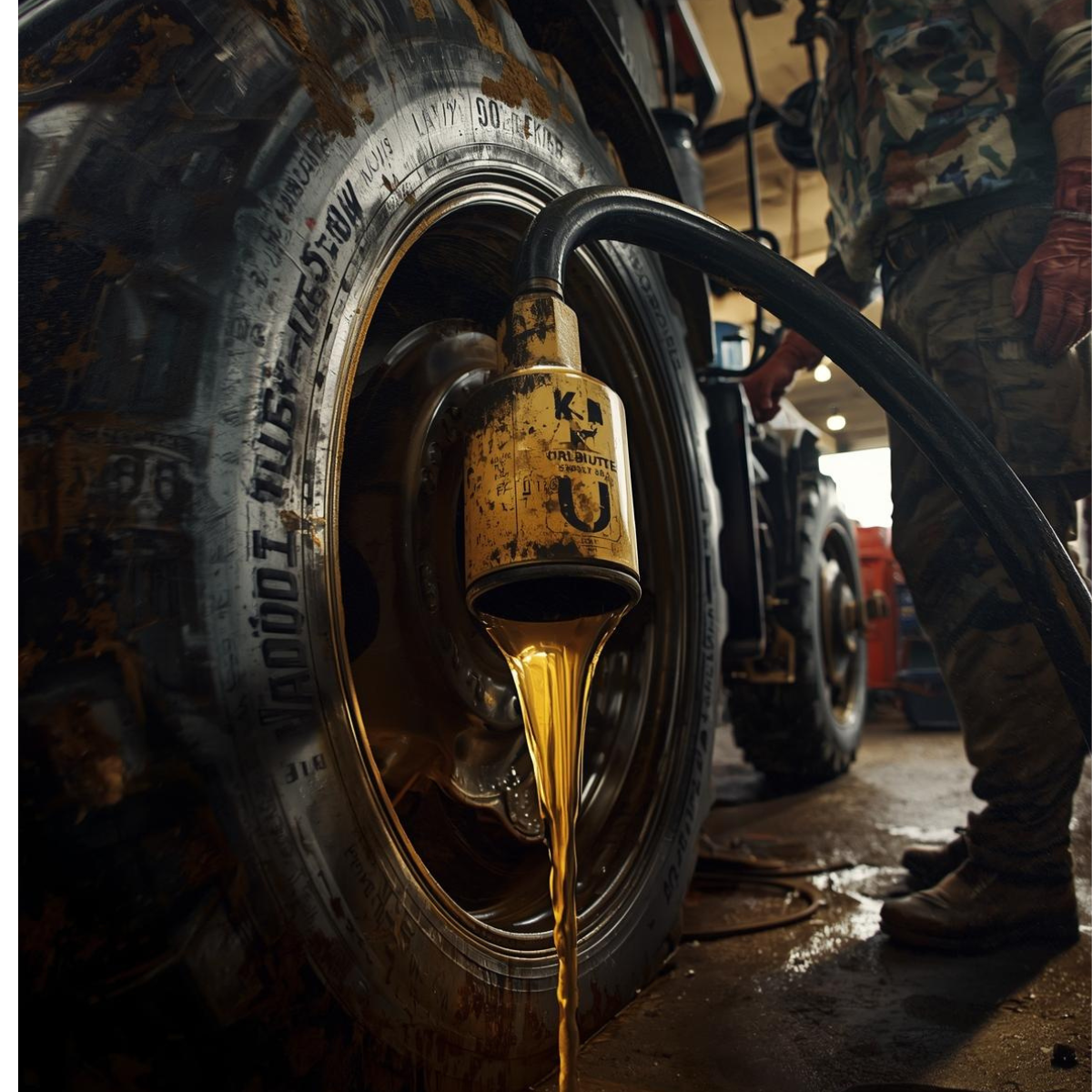

Smart Winter Storage: Reduce Condensation and Clogged Filters

Storage is where many winter problems begin, especially on tractors that sit between jobs. Start by topping off the tank, because a full tank leaves less space for condensation. Then add a diesel conditioner or stabilizer if the machine may sit for weeks. Keep cap areas clean, so grit doesn’t fall into the tank during fueling. If your tractor has a water separator, drain it regularly and record results. Even small amounts of water can freeze and block the flow at the filter head. Also, replace old fuel filters before winter, as cold, thick fuel can cause restrictions. During long storage, run the tractor monthly to circulate treated fuel and warm fluids. Meanwhile, maintain the battery, since slow cranking can mimic fuel trouble. Finally, store fuel cans indoors and keep them sealed, because open vents draw in moisture. For storage questions and parts, Bob’s Tractor Parts in McEwen, TN, is a dependable resource.

Block Heaters and Cold Starts: What Really Helps

A block heater can make winter starts feel normal, especially after a freeze. It warms the coolant and the block, so oil flows faster, and combustion stabilizes sooner. That means less smoke, less strain, and calmer first minutes. However, a block heater can’t fix a weak battery or worn glow plugs. Plug it in two to three hours before starting, or use a timer. In most Tennessee cold snaps, longer than four hours brings little benefit. Keep plugs dry and covered. Use a heavy outdoor extension cord, and keep connections off wet ground. Also, inspect the cord, because cracked insulation can trip breakers or shock you. If your tractor has an intake heater, let it cycle fully before cranking. Then crank in short bursts, giving the starter time to cool between attempts. Bob’s Tractor Parts can help you choose heaters, cords, and glow plug parts that fit your LS model.

Water in Fuel: Signs, Causes, and Fixes

Water in diesel causes more winter headaches than many owners expect. It comes from condensation, poor storage cans, or fuel that sat through humid months. Once temperatures drop, that water can freeze into crystals that block the filter media. You may notice power loss, surging, or a tractor that starts then dies. First, drain the water separator, and replace the filter if it looks dark or swollen. Next, inspect the tank for slime, because microbes feed where water meets diesel. If you see contamination, you may need a biocide and a fresh filter set. Also, keep cans sealed and labeled, so old fuel doesn’t sneak into your tractor. For bulk tanks, use a desiccant breather to reduce moisture pulled in overnight. Then, store equipment with fuller tanks, because empty space creates condensation. When problems persist, Bob’s Tractor Parts can test, troubleshoot, and help you restore clean fuel flow.

A Simple Winter Routine and When to Call Bob’s Tractor Parts

A winter routine keeps diesel equipment ready, even when Tennessee weather can’t make up its mind. Start with clean winter-blend fuel, and add anti-gel before the first hard freeze. Then keep tanks fuller, drain separators, and replace filters nearing the end of their service life. Next, protect starting power with a healthy battery and a block heater when needed. Also, warm up slowly, as cold oil needs time to warm. Carry spare filters and basic tools to keep downtime short. Keep the machine under cover to reduce ice buildup. If the tractor stumbles, don’t push it, because clogged filters can starve the injection system. Instead, stop, check for water, and fix the issue early. Near McEwen, Bob’s Tractor Parts is the place to get answers fast. They provide best practices, parts, and repair services for LS tractors. With the right support, your tractor starts confidently and works safely all winter long.